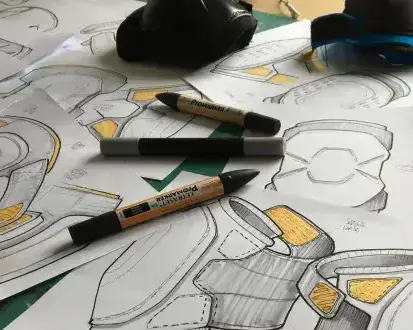

Rethinking our design,

reducing our environmental footprint

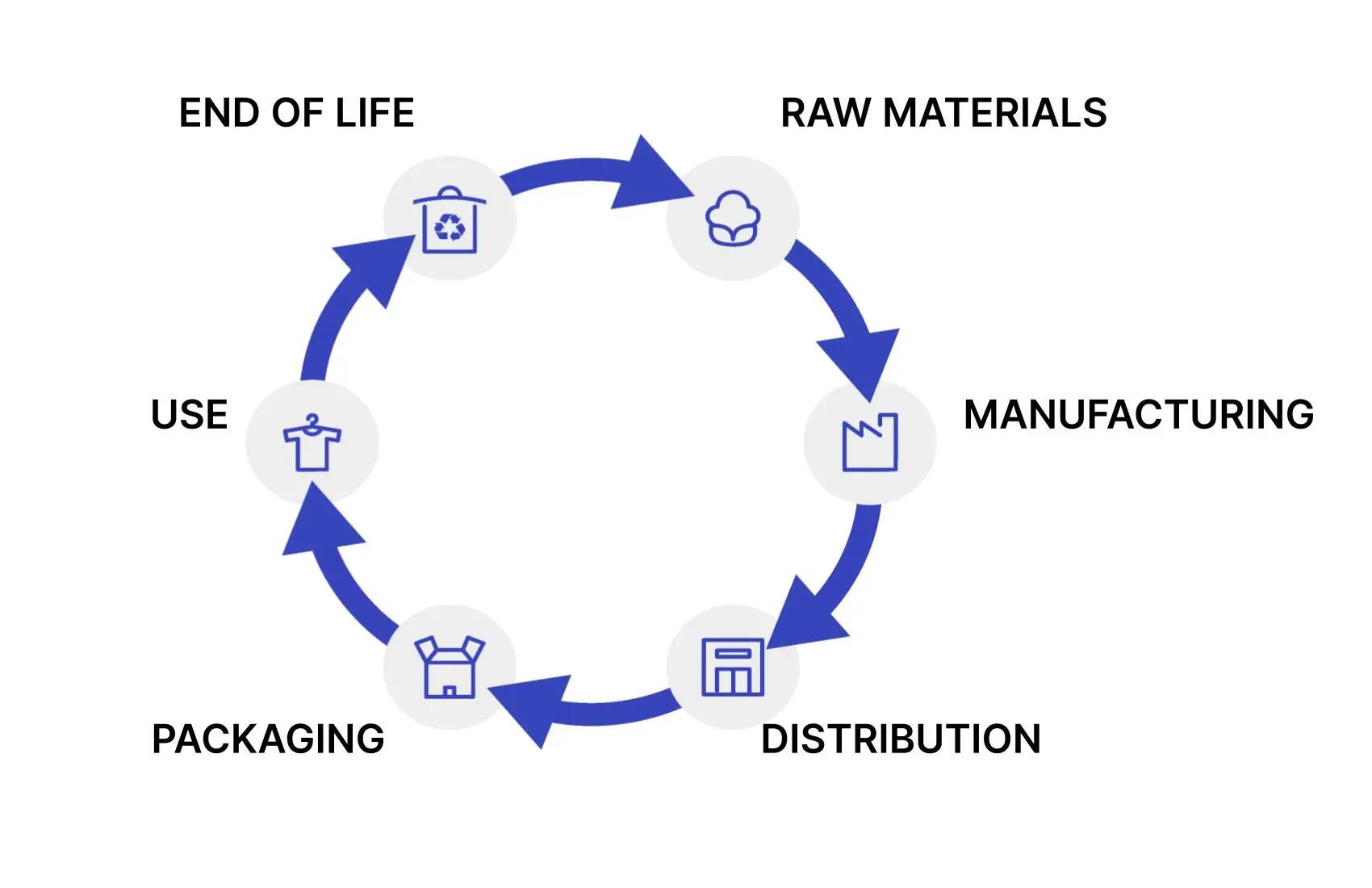

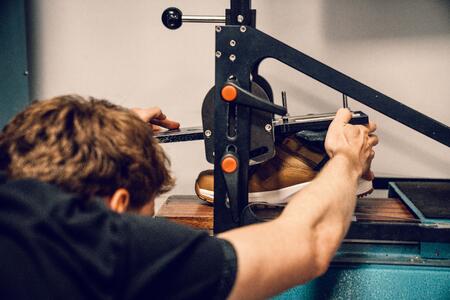

In 2024, raw material extraction and product manufacturing made up 60.7% of our carbon footprint, highlighting the crucial need to target these areas first. By designing and producing our own products, we can actively reduce our environmental impact through strategic choices in materials and processes.

Our ecodesign approach is a top priority. A key part of our commitment to achieve the Net-Zero goal by 2050, aiming for a 90% reduction in our greenhouse gas emissions.