The first step: identify a product's principal faults

In other words, how do you know what is likely to get damaged on a product?

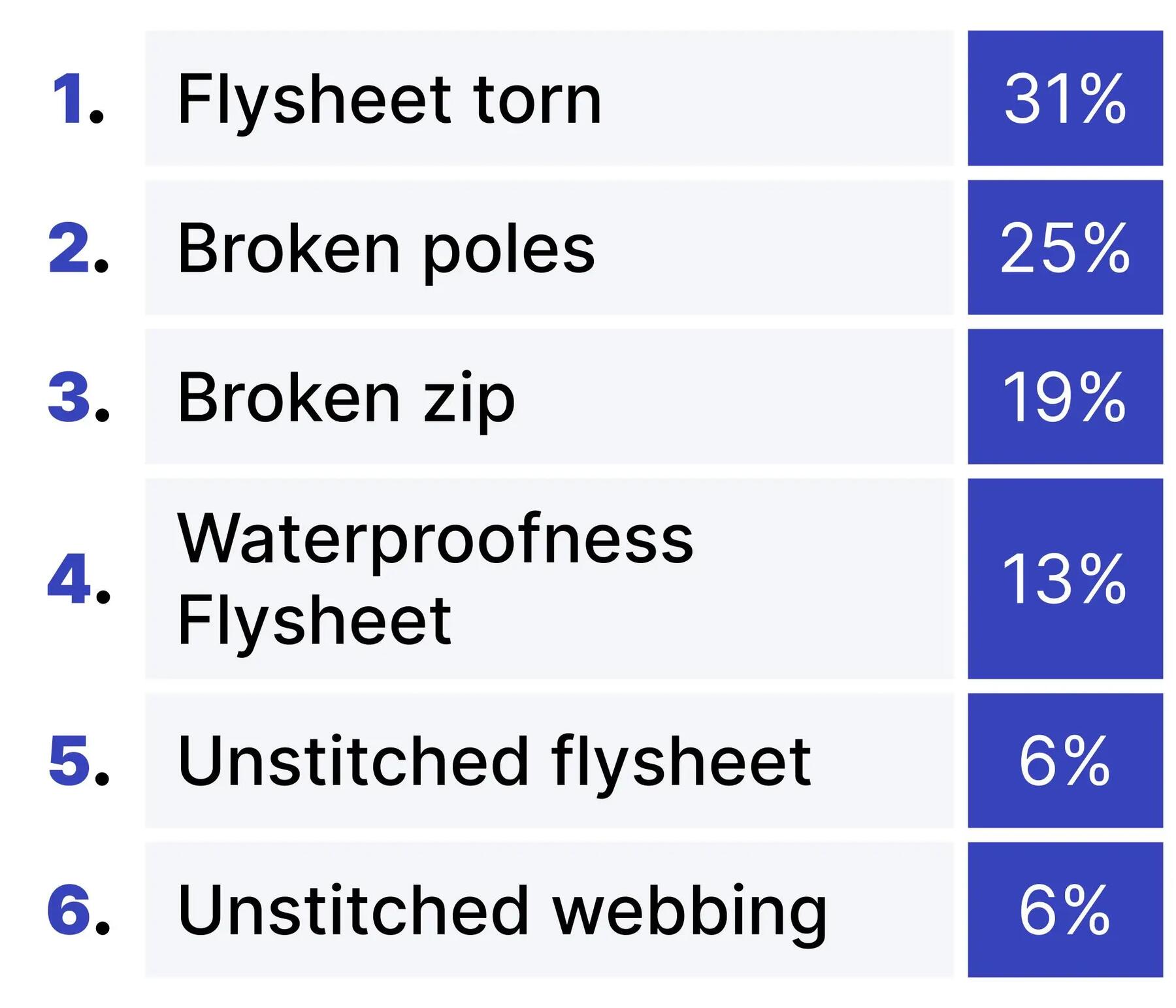

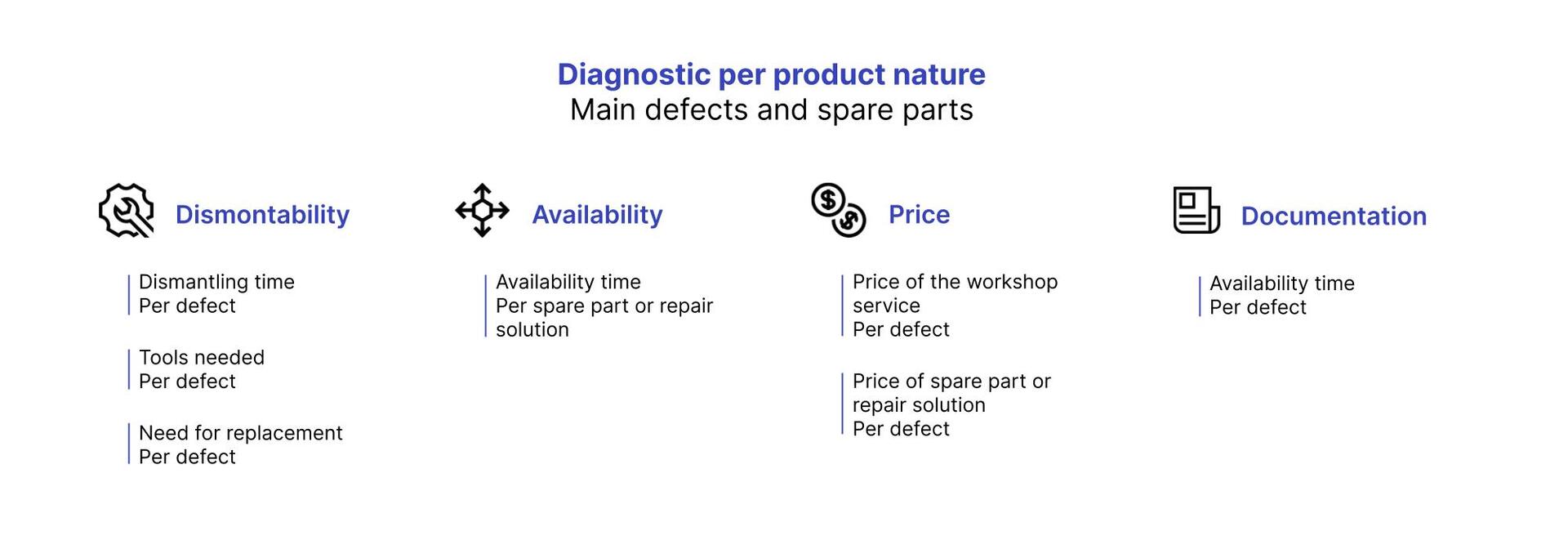

This is a crucial stage: the rest of the methodology stems from this. Subsequently, people in charge of collecting the available data have to carefully work out from the data to understand (and quantify) what are a product's principal faults.

What this means in practice is that a network of specialists, within DECATHLON, is responsible for analysing these faults, by product type.

Those who want to become a specialist must take a 2-hour course to understand the methodology to analyse faults.