How is post-consume polyester made work?

Post-consumer recycling focuses on materials that have already been used, such as clothes or products made of polyester. While DECATHLON initially mainly used recycled polyester made from plastic bottles, it is now also turning to textile waste.

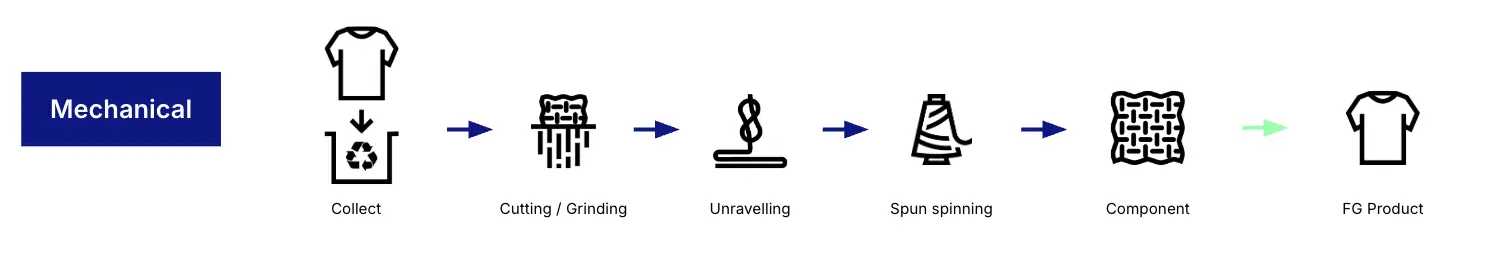

The first stage consists of collecting this waste. Various channels exist, such as sorting centres, in-store collection or buyback schemes offered by certain brands. Once collected, these textiles are sorted by colour and composition to separate the polyester from the other materials. It is then necessary to meticulously clean them to eliminate impurities such as food or dirt.

Today, in 2025, post-consumer recycling, does not yet represent the majority of recycled polyester used by DECATHLON. This is down to the complexity of a sector, which still needs to be structured and optimised. Collecting, sorting and processing post-consumer textile waste require investment and innovation to guarantee the quality and traceability of recycled materials.