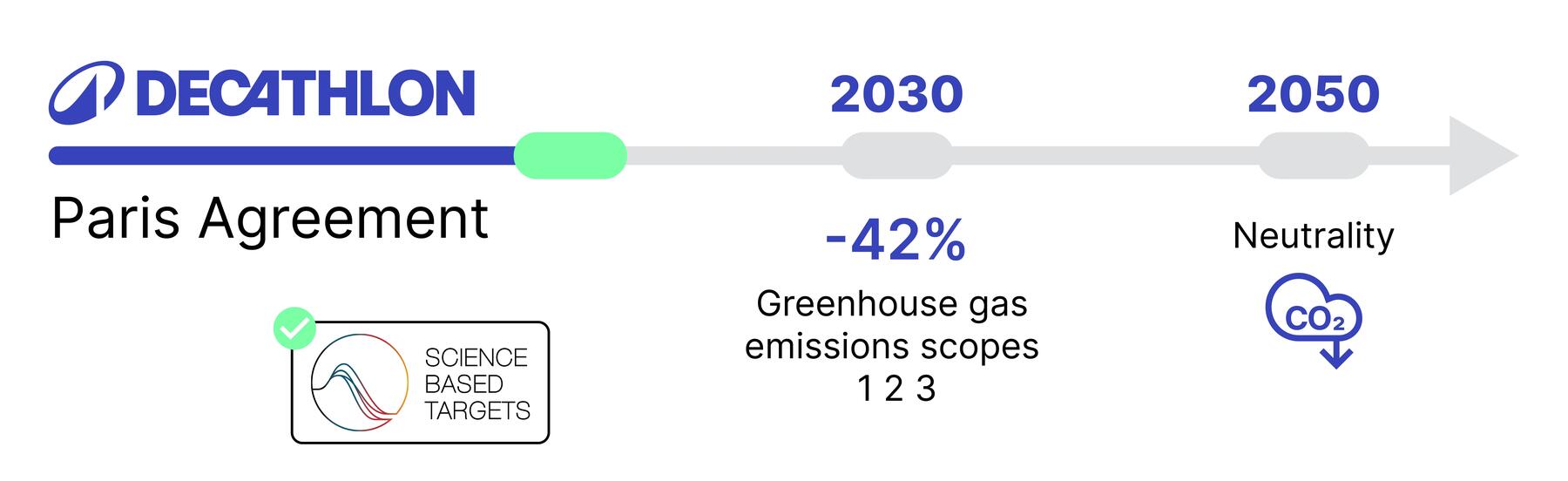

DECATHLON commits to reach net-zero greenhouse gas emissions across the value chain by 2050.

At DECATHLON, we are aware that our activities have a major impact on our environment, our playgrounds. As sportsmen and women, we see this every day on our playgrounds.

This is why DECATHLON is committed to contributing to achieving carbon neutrality by 2050, in accordance with the Paris Agreement.