The glossary

Polyester, polyamide, polyester, cotton... recycled cotton, cellulose fibre, Lyocell or even solution dyed, the world of conception is not always a piece of cake.

We have put this glossary together to help you navigate through it.

Avoided emissions

In addition to their carbon footprint, companies can assess the decarbonizing power of their products and services when they allow others (customers, partners, suppliers, etc.) to reduce their emissions.

The objective is to compare the company's solutions with its alternative on the market to fulfill the same purpose.

Let's take an example... at DECATHLON, at random. This would be the sale of a used bike rather than a new bike. As you can guess, the resale of this bike emits less carbon than if a new one had been made: carbon emissions have therefore been avoided. Another example is the purchase of a bike to commute: our lucky cyclist replaces some of his car trips with bike trips. Using a bike avoids the use of more carbon-intensive means of transportation, and if the sale of the bike is counted in DECATHLON's carbon footprint... it also contributes to planetary carbon neutrality, and we value that through the emissions avoided.

Cellulosic fibres (lyocell, modal...)

Cellulosic fibres are synthetic fibres, 100% cellulosic and biodegradable, produced from wood pulp (principally from Eucalyptus but also Oak or Birch) dissolved into a non-toxic and recyclable solvent.

Cold pad batch

Cold pad batch is a colouring process done at room temperature that helps to use less energy and, therefore, emits less CO2. It also uses less water compared to traditional dyeing techniques.

Durability

Greige

Greige is the colour of the fabric's natural state, in other words, undyed. What, actually, is the connection between colour and pollution? Well the process of colouring textiles has a big environmental impact, on energy consumption and involves using lots of water and chemical products when soaking them in the dyeing vats. So choosing greige, therefore, means selecting the colour that pollutes less.

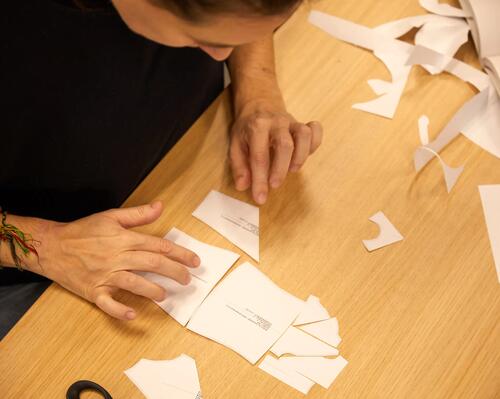

Minimal waste design

Organic cotton

Cotton from organic farming is grown without using chemical fertilisers, pesticides or GMOs, reducing the risk of soil and groundwater contamination. Thanks to a more environmentally responsible practices, this method of production helps to better manage cotton growing.

Using these organically grown cotton fibers enables to reduce the CO2 emissions associated with yarn production by at least 2,4% compared with conventional cotton.

Recycled cotton

Recycled polyamide

Polyamide is a synthetic material made from fossil fuel-based resources. Using recycled polyamide means collecting and reprocessing production offcuts or products destined for landfills instead of using new fossil fuel-based resources.

Recycled polyester

Polyester is a recycled material reprocessed from production offcuts or products destined for landfills, preventing the use of new fossil-fuel based resources.

Using these recycled polyester filaments enables to reduce the CO2 emissions linked to yarn production by at least 16% compared with using virgin polyester.

Recycled polypropylene

Using recycled polypropylene helps to prevent the use of fossil fuel-based resources.

Polypropylene is a synthetic material made from fossil fuel-based resources. Using recycled polyamide means collecting and reprocessing production offcuts or products intended for landfills instead of using new fossil fuel-based resources.

Recycled rubber

Recycled rubber reduces the use of virgin oil resources. Bonus: it is often made from used tires. Recycled rubber can be used in shoe soles or sports equipment as a replacement for virgin rubber.

Recycled wool

Using recycled wool is interesting because it does not require farming sheep again to produce wool. However, it is only possible up to 25% (for a t-shirt) and approximately 70% (for a layer 2 such as a pullover), because the fibres are shorter and have to be combined with other fibres to meet user features.

Using these recycled wool fibers enables us to reduce the CO2 emissions associated with yarn production by at least 24%, compared with using virgin wool.

Repairability

Single yarn dyeing (Bi-ton)

Dyeing fabric requires using large amounts of water, and also producing waste water coming from the dyeing vats. The single yarn dyeing technique (also knows as bi-ton) helps to reduce this environmental impact by dyeing one out of every two fabric threads, subsequently reducing consumption and the impact on water.

Solution dyed

Solution dyed involves integrating colour pigments directly when spinning the yarn. The benefit of solution dyeing is that it saves energy (carbon impact) and water. The solution-dyed is a polymer. In the colour's formula, there is a pigment, a dye that produces the tint. These two components (the main polymer and the colour formula) are heated up and mixed in an endless screw, an extrusion of which comes out a yarn. All that remains to do is stretch and spin it around a reel.

This colour impregnation means integrating colour pigments when spinning the yarn, helping to reduce the considerable environmental impact of dyeing associated with water usage and contamination.

Waterless dyeing

"Waterless dye" is a dyeing process that works with CO2 in a closed loop, with 95% being reusable. Using a certain amount of heat and pressure, the CO2 acquires properties that permeate and carry the dye into the fabric without using water, helping to reduce the impact compared to standard dyeing.