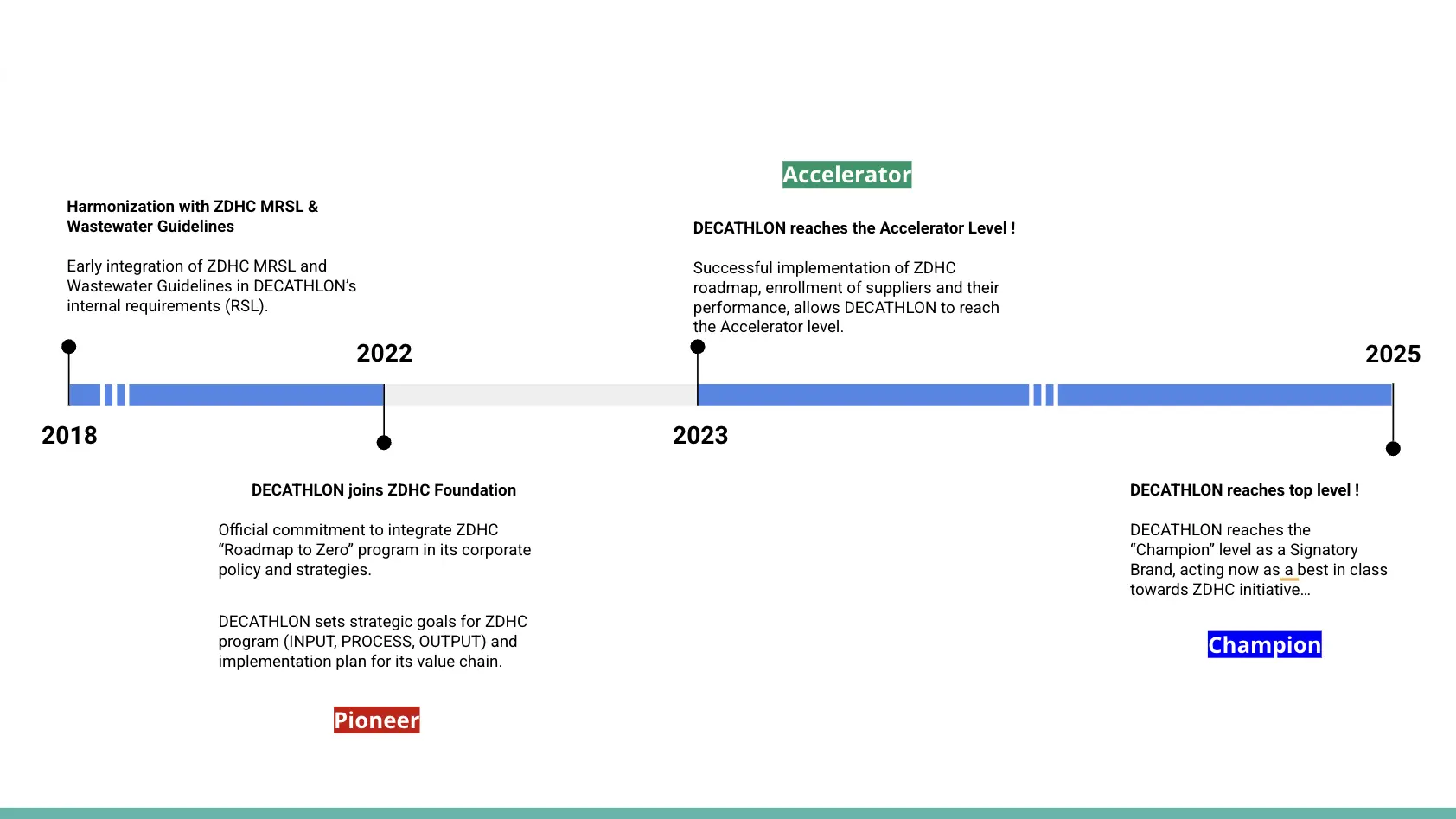

Our commitment to ZDHC program

DECATHLON SE is committed to supporting the ZDHC’s mission to enable the textile, leather, apparel, and footwear industries to implement best practices for the sustainable management of chemicals throughout the value chain. Through collaboration and with the overall aim of harmonising industry practices, defining standards and implementing them, the ZDHC Foundation is committed to achieving zero discharge of hazardous chemicals.

Company commits to support the ZDHC’vision of the widespread implementation of sustainable chemistry, driving innovations and best practices in textile, apparel, and footwear industries to protect consumers, workers and the environment.

DECATHLON's commitment to ZDHC applies to the entire group (including individual brands within DECATHLON) linked to the ZDHC scope. Consequently, all suppliers working with DECATHLON and involved in the manufacture of textiles, leather, clothing or footwear are required to apply DECATHLON's requirements to the ZDHC program, whether the factory is a producer of components or finished products.

DECATHLON adopts the ‘ZDHC MRSL’ and ‘ZDHC Wastewater Guidelines’ in their entirety, and commits to comply with the ‘ZDHC CMS’ (Chemical Management System), ‘TIG’ (Technical Industry Guide) and ‘MMCF’ (Man Made Cellulosic Fibers) guidelines. DECATHLON is committed to participating and being involved in the creation, development, testing, improvement and joint implementation of the ZDHC program (‘Roadmap to Zero’, guidelines, training, solutions and any initiative that advances the ZDHC mission and vision.