What is biomass balance for?

And the reason we are telling you about it

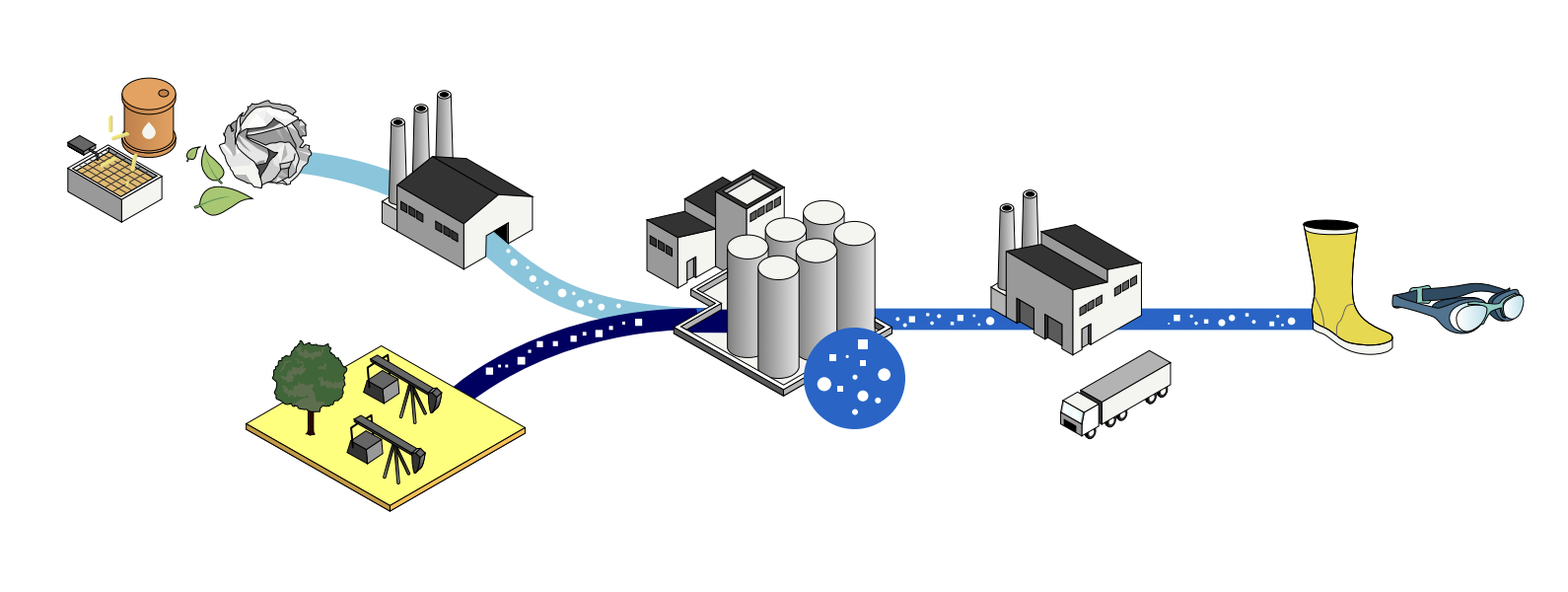

Profoundly changing how an industry operates is a big deal. It takes time, and it is expensive. In short, it is not easy to win over certain people and convert to being fossil fuel free. It might even be possible today to run industrial equipment exclusively with alternative raw materials (the volumes are too small to meet demand). This is where the biomass balance material concept comes into it. Interesting.

By letting suppliers join in a transition process, we are contributing to reducing the use of fossil fuels, even if it is little by little.

The purpose is to also get it integrated into existing production lines, accelerating implementation of this production method without building new factories… The cherry on the cake: the material's resulting properties remain the same.

In some cases, it might lead to upcycling waste. We will tell you more about this afterwards.