Product feasibility: is this going to work?

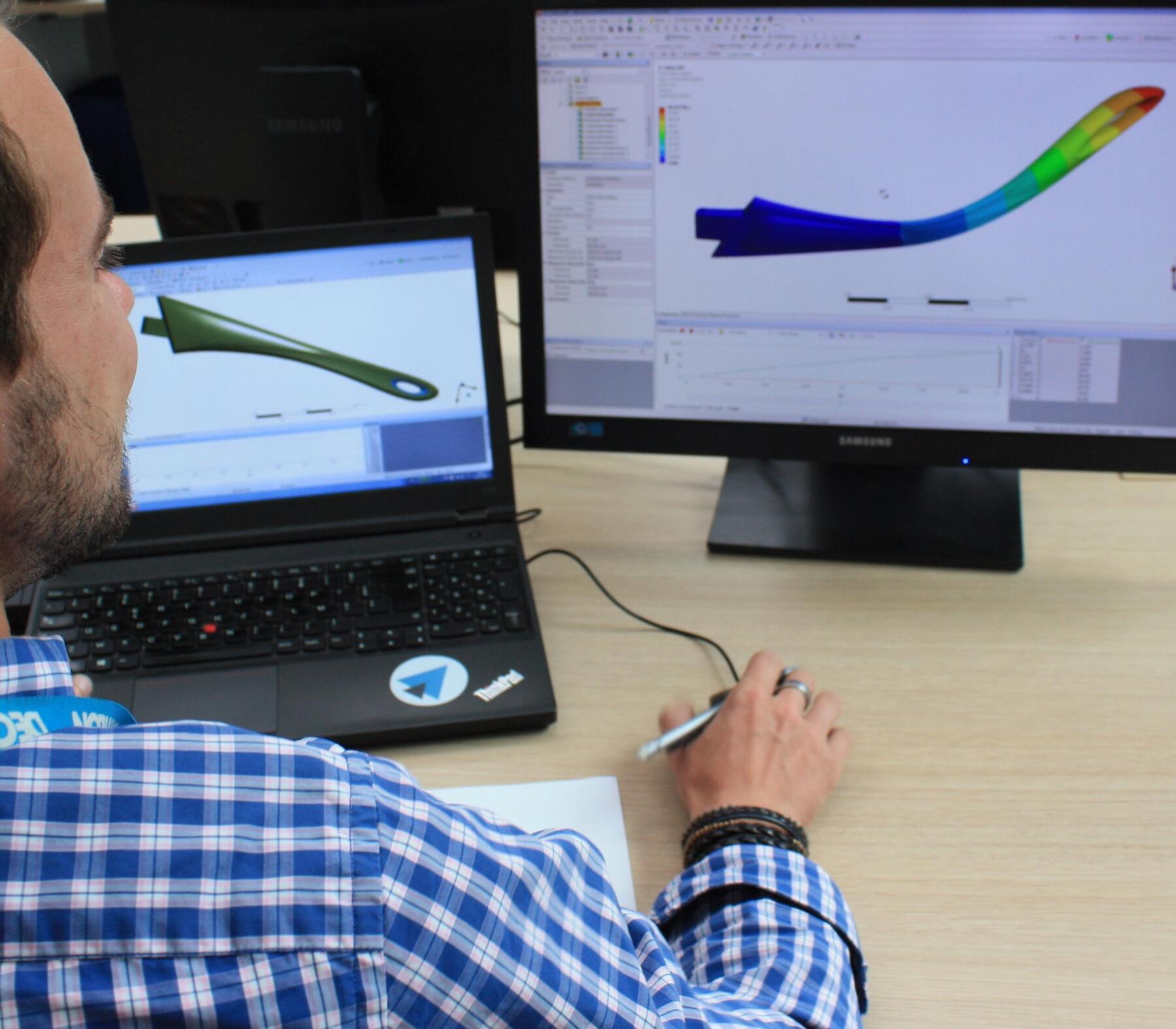

Our design team make the future product a reality.There are already its main features thanks to computer-assisted design (CAD). And with the 2D/3D drawings and the first prototypes, we also checked it complies with the specifications..

Last step: evaluate feasibility.. To do so, we ask ourselves several questions about the aesthetics, the components, the technical skills, the right manufacturing price, the patents, etc.

Once we've carefully checked all these, there are either two options: do we go with it or not!

If the feasibility is approved, it's go. We launch the first prototypes.

If it's not approved, we rethink the product, or certain product aspects and its design to pursue the project.

in the picture: CAD helps us to materialise the first sketching.