The technical file

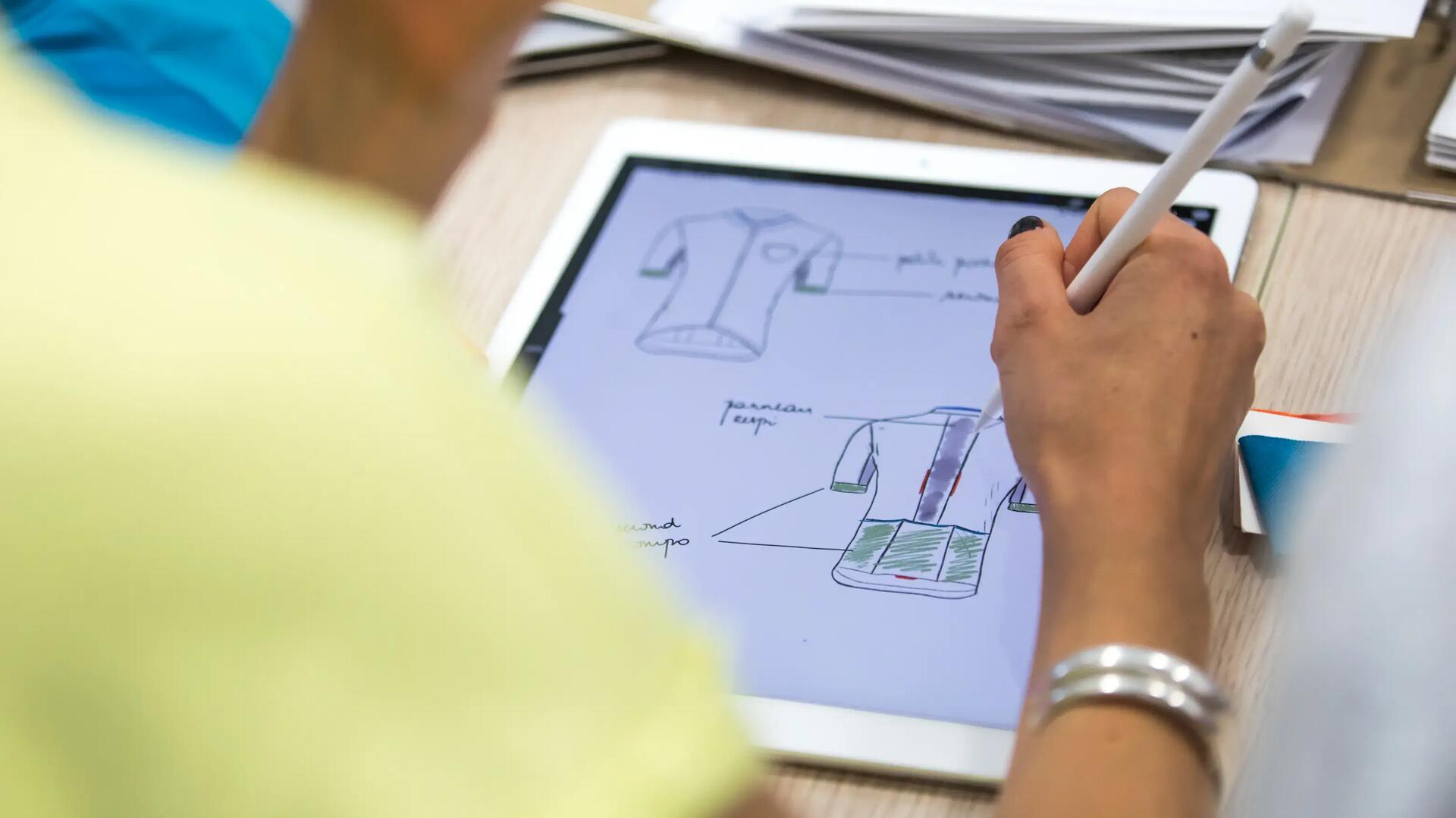

This involves real teamwork!

Each member of the team takes part in drafting the technical file. Here are some examples:

→ The product engineer completes the future product's list of components. This is referred to, in the jargon, as the BOM: Bill of Materials. By sending this list to the DECATHLON teams in different countries, we can get detailed information about the price, the manufacturing lead times, etc.

→ The packaging engineer creates the packaging and provides all the technical details for its mass production. Good to know: the industrial prototype includes the product and its packaging. It is more practical for anticipating manufacturing costs and saves time.

→ The garment maker formalizes the pattern cutting when it's for a clothing product. She or he creates the assembly instructions, including the design rules to comply with. This is all done working collaboratively with the methods engineers or the prototype maker.

→ The mechanical design engineer puts together the mould's 3D plans required to make the prototype. It provides detailed technical specifications for producing the mould.

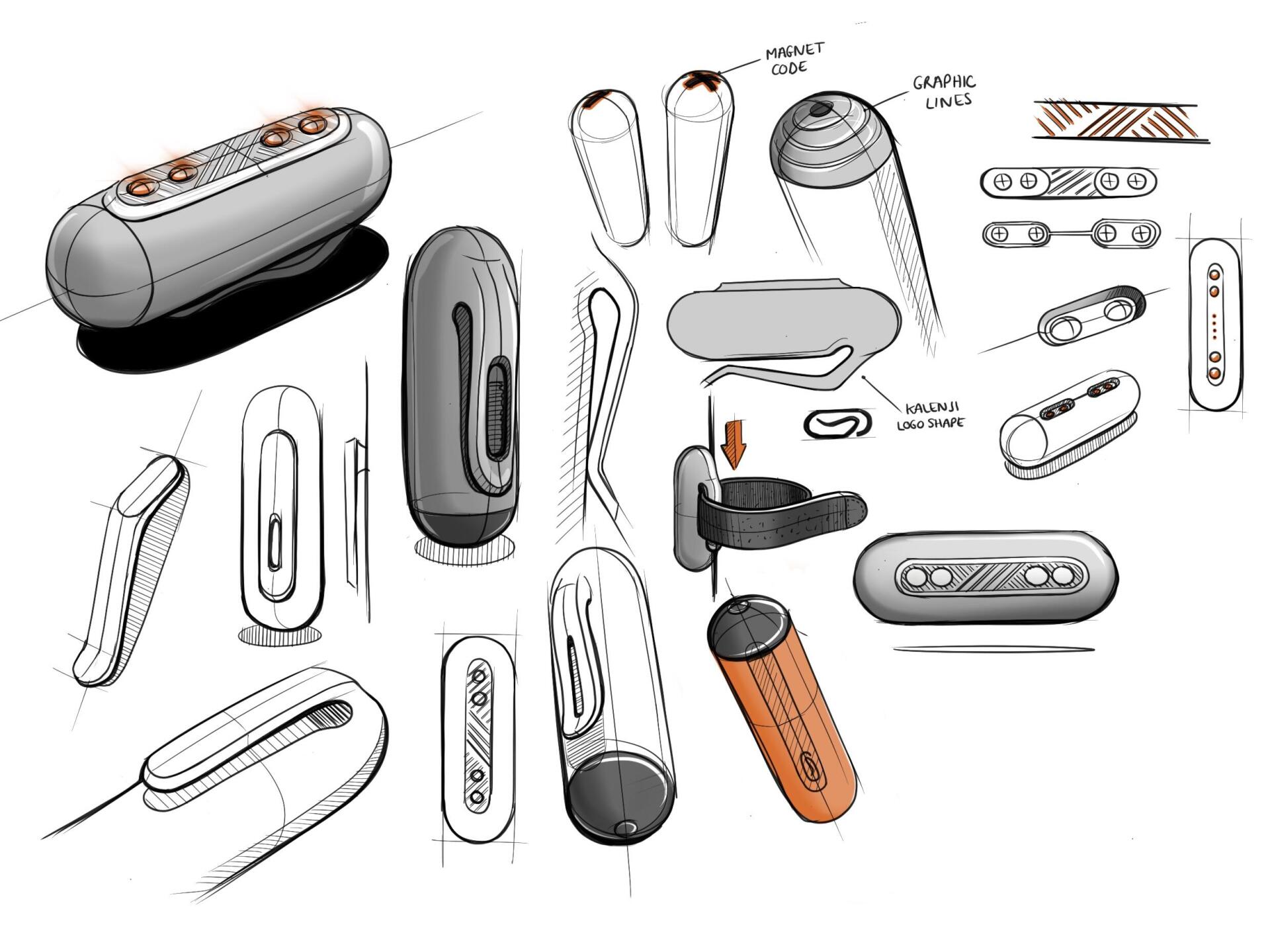

→ The designer specifies their aesthetic intentions, in other words what they want the product to look like. The best aesthetic intentions are selected with the other members of the team. Then they prepare the technical file with among other things, the dimensions, the colours, in tandem with the product engineer.