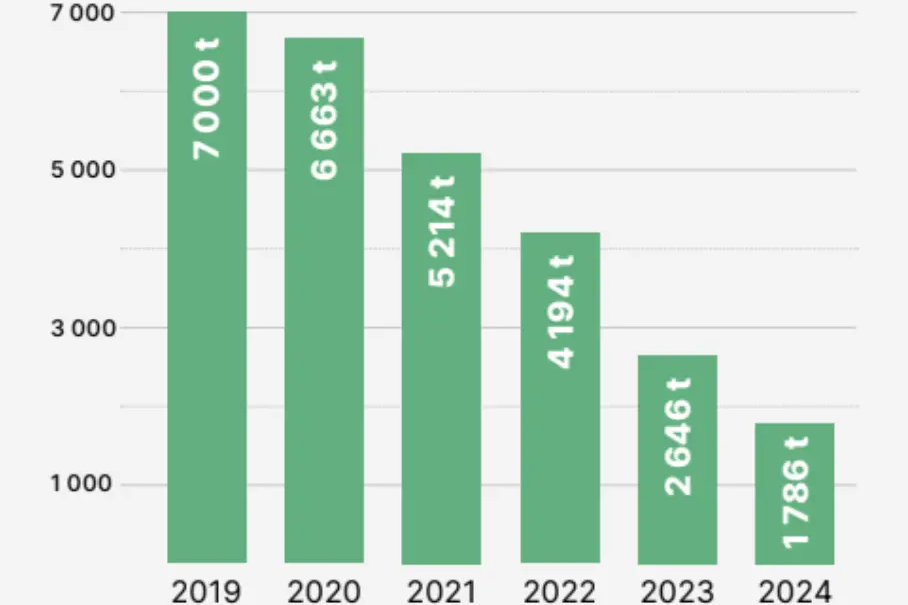

Measuring and reducing DECATHLON's impact

DECATHLON is conducting research and modelling work to measure and ultimately reduce the plastic pollution footprint its activities generate. In 2024, the teams updated the review of the company’s plastic pollution footprint at the Group level, as well as for countries, sports and industrial processes, using a dynamic management report developed with Environmental Action in 2023.

This report uses methodologies developed by the Plastic Leak Project and the Plastic Footprint Network and aims to make data reporting reliable and automated.

Teams are using this new study to create a reduction trajectory that aims to keep the company’s activities within planetary boundaries. To this end, they have already identified levers to be activated:

- Strengthening circular business models (second life, rental, repair)

- Replacing single-use plastics with alternatives having less of an impact

- Recycling sports equipment at its end of life, and managing waste.

Through these studies, Decathlon also aims to help create an international standard that will ultimately include plastic-use reduction objectives in a legal framework that applies to all industry players.