The emergence of the concept

Like the Sunday dressmaker, the textile industry is also confronted with this thorny problem. In fact, despite its increasingly sophisticated techniques, the average efficiency in this area is estimated at 85%. In other words, in factories all over the world, 15% of the fabric is still lost when cutting the pieces that make up the garments.

Aware of the urgency to reduce this waste, a number of players in the industry are trying to act, seeking new strategies to rationalize their consumption of fabric. A new concept has emerged within the industry called "zero waste design".

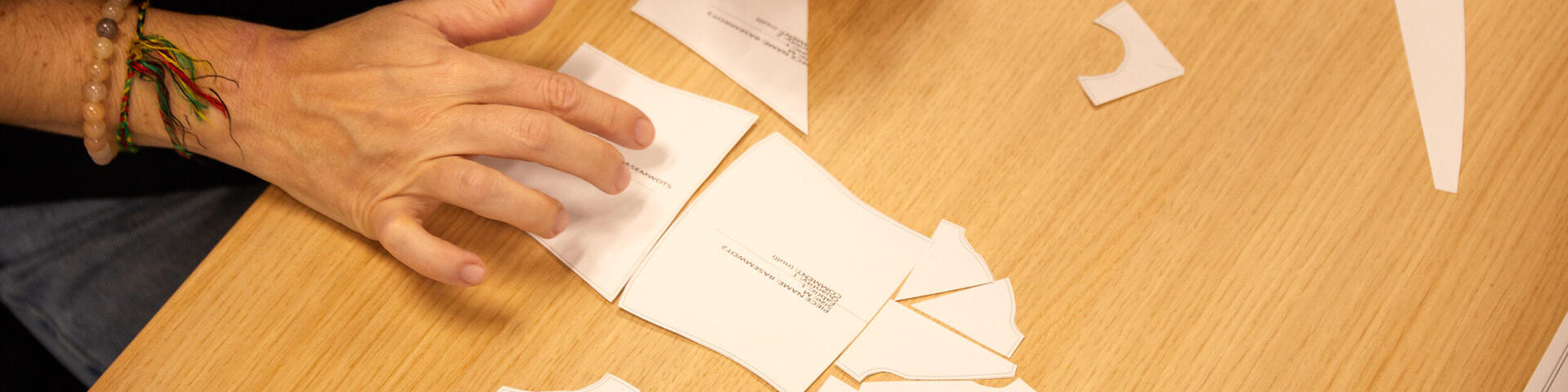

"The term "zero waste design" appeared about 20 years ago and refers to a set of methods that aim to optimize the raw material, in this case fabric, from the design phase of a garment in order to throw away as little as possible during the production phase," says Marie Romeuf, pattern maker for Domyos and member of DECATHLON's minimal waste design team.

Over time, a second expression has been added to the initial concept: "For textiles, zero waste is still a somewhat distant ideal," says the designer, "so, to be more faithful to reality, we also use the term 'minimal waste design'. In French, this means "design with a minimum of waste".