The ecodesign approach

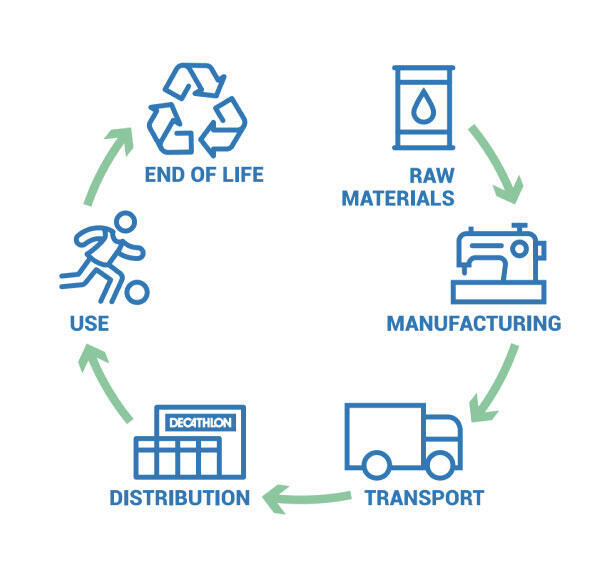

Eco-design involves taking the environment into account from the earliest stages of design and throughout the product's entire life cycle.

In practical terms, this means thinking about how to reduce the product's impact on the environment throughout its life cycle.

A product that has been designed (or redesigned) using an eco-design approach remains a product that fulfils the same function as a conventionally designed product: a running T-shirt that has benefited from an eco-design approach remains, above all, a good running T-shirt!